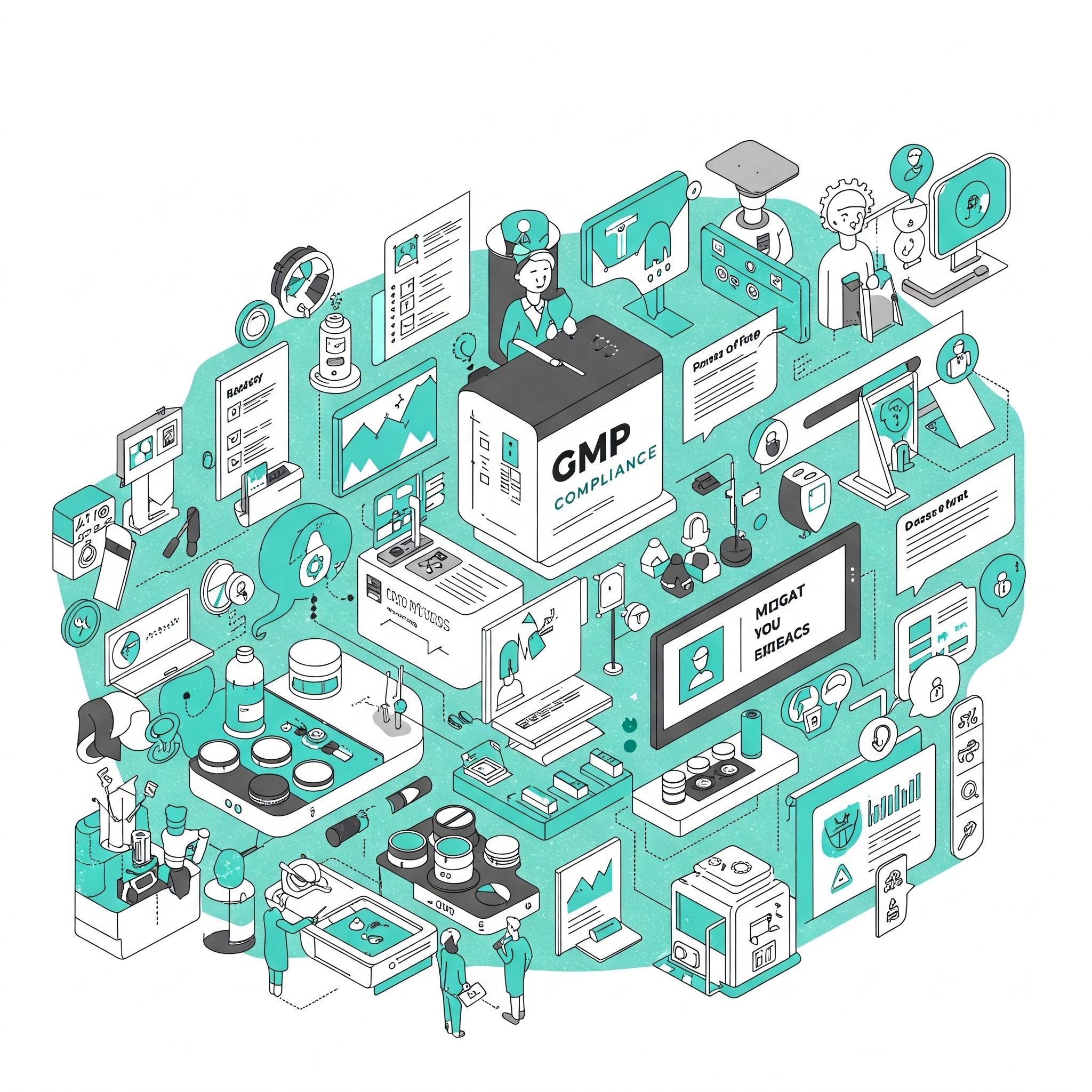

Risk Management in Cosmetics GMP: Ensuring Quality and Compliance

In today’s dynamic cosmetics market, consumer trust and regulatory compliance are paramount. For manufacturers, adhering to Good Manufacturing Practices (GMP) is not just a recommendation—it’s a critical foundation for producing safe, high-quality products. Increasingly, global regulators and industry standards for cosmetics are emphasizing a proactive, risk-based approach to GMP. This means moving beyond static procedures to actively identify, assess, control, and monitor potential risks across your operations.

Why Risk Management is Essential in Cosmetics GMP?

Historically, GMP adherence might have focused on checklists and reactive problem-solving. However, modern expectations require a more sophisticated strategy. Regulators expect cosmetic companies to:

- Anticipate and Prevent: Proactively identify potential hazards and risks before they lead to quality issues, contamination, or non-compliance.

- Justify Decisions: Base operational decisions (e.g., process design, equipment selection, cleaning frequency) on a clear understanding and justification of associated risks.

- Continuously Monitor: Establish systems to regularly review and update risk assessments as processes, ingredients, or regulations change.

Applying Risk-Based Thinking Throughout the Cosmetic Product Lifecycle

The principles of risk management should be embedded into every stage of your cosmetic product’s lifecycle, from concept to consumer. This includes:

- Product & Process Design:

- Ingredient Selection: Assessing risks associated with raw material sourcing, stability, and potential contaminants.

- Formulation Development: Identifying critical process parameters and potential risks to product stability, safety, and efficacy during formulation.

- Packaging Design: Considering risks related to packaging integrity, compatibility with the product, and potential for migration.

- Facility & Equipment:

- Layout & Flow: Designing facilities to minimize cross-contamination and ensure logical material and personnel flow.

- Equipment Qualification: Assessing risks related to equipment performance, calibration, and suitability for its intended use (e.g., mixing tanks, filling machines).

- Cleaning & Sanitation Validation: Developing and validating cleaning procedures based on the risk of microbial contamination or residue carry-over.

- Operations & Production:

- Manufacturing Processes: Identifying critical control points in blending, filling, and packaging operations.

- Environmental Monitoring: Establishing appropriate monitoring programs for cleanrooms or controlled environments based on the risk to product quality.

- Data Integrity: Implementing controls to ensure the accuracy, completeness, and consistency of all manufacturing data.

- Supply Chain Management:

- Raw Material Qualification: A robust risk-based program for qualifying suppliers of ingredients, packaging, and other critical materials, including audits and ongoing performance monitoring.

- Outsourced Activities: Managing risks associated with contract manufacturing, testing, or other outsourced services.

Introducing COS-GMP: Your Risk-Based Framework for Cosmetic Excellence

While the principles of risk management are clear, implementing them effectively requires a structured approach. At ApexGlobal Quality, our COS-GMP standard is specifically designed to provide cosmetics manufacturers with a robust, risk-based GMP framework.

COS-GMP goes beyond generic guidelines by offering:

- Tailored Risk Assessment Tools: Practical methodologies and templates to systematically identify and evaluate risks unique to cosmetic ingredients, processes, and products.

- Structured Control Measures: Guidance on implementing effective control strategies that are proportionate to the identified risks, from facility design to validation protocols.

- Continuous Improvement Cycles: Mechanisms for ongoing risk review and monitoring, ensuring your quality management system remains agile and responsive to new challenges or regulatory updates.

- Compliance Made Practical: Translated regulatory expectations into actionable steps, helping you build a GMP system that not only meets requirements but also drives efficiency and quality.

By adopting COS-GMP, you gain a clear roadmap for integrating risk management into every facet of your cosmetic manufacturing operations, ensuring that quality and safety are built-in, not just inspected for.

Benefits of a Proactive, Risk-Based Approach to Cosmetics GMP

Embracing a comprehensive risk management strategy offers significant advantages for cosmetic manufacturers:

- Enhanced Product Quality & Safety: Minimized risk of defects, contamination, and product recalls.

- Improved Efficiency: Streamlined processes, reduced deviations, and less wasted resources.

- Greater Regulatory Readiness: Confidence in audits and inspections, demonstrating a robust quality management system.

- Stronger Supplier Relationships: Better collaboration and higher confidence in the quality of incoming materials.

- Sustained GMP Excellence: A culture of continuous improvement and proactive problem-solving.

By systematically integrating risk management into your Cosmetics GMP framework, you not only ensure compliance but also build a more resilient, efficient, and reputable manufacturing operation.

Get a copy of COS-GMP now for free

Totally free, forever