AQL Checklists

£15.00

What’s Included

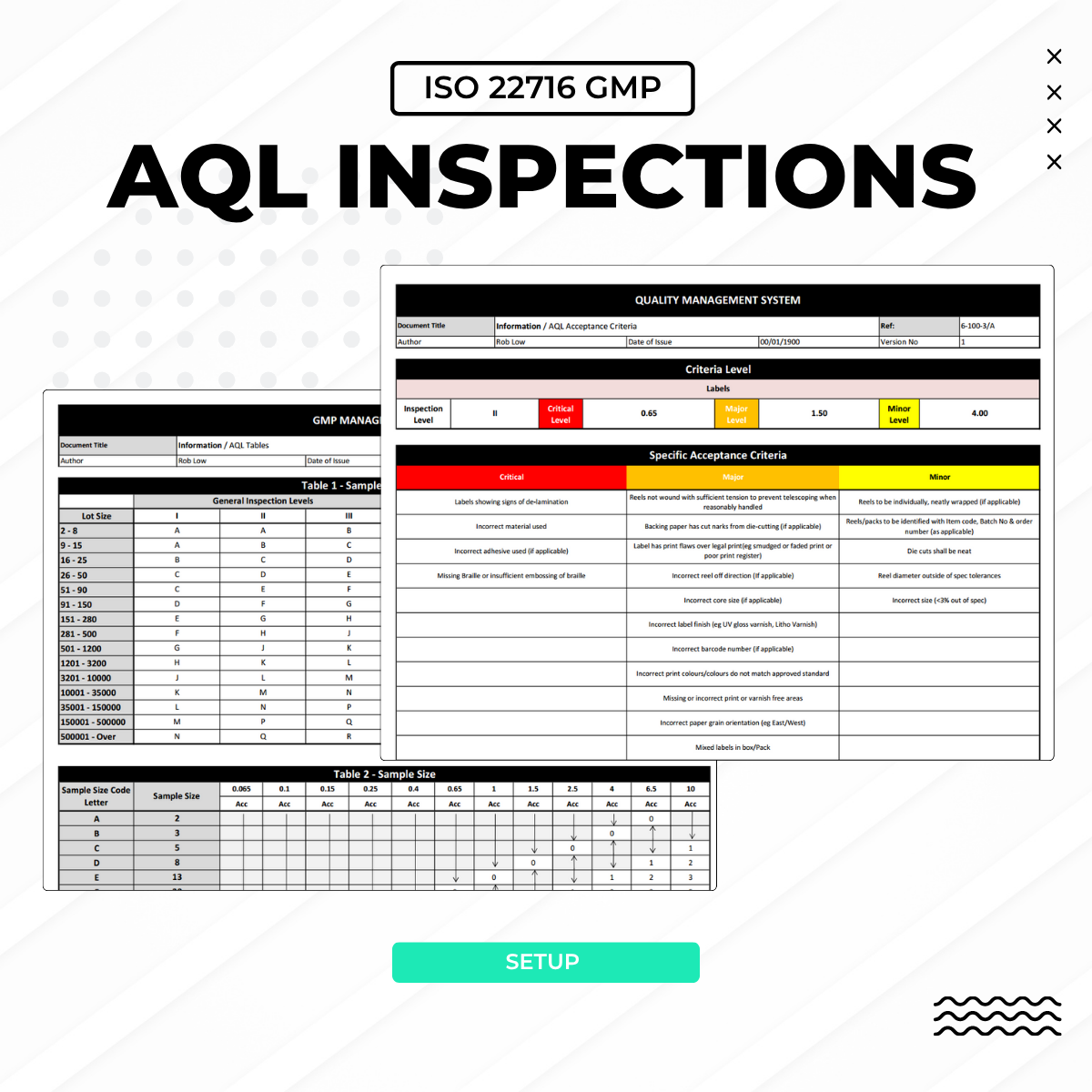

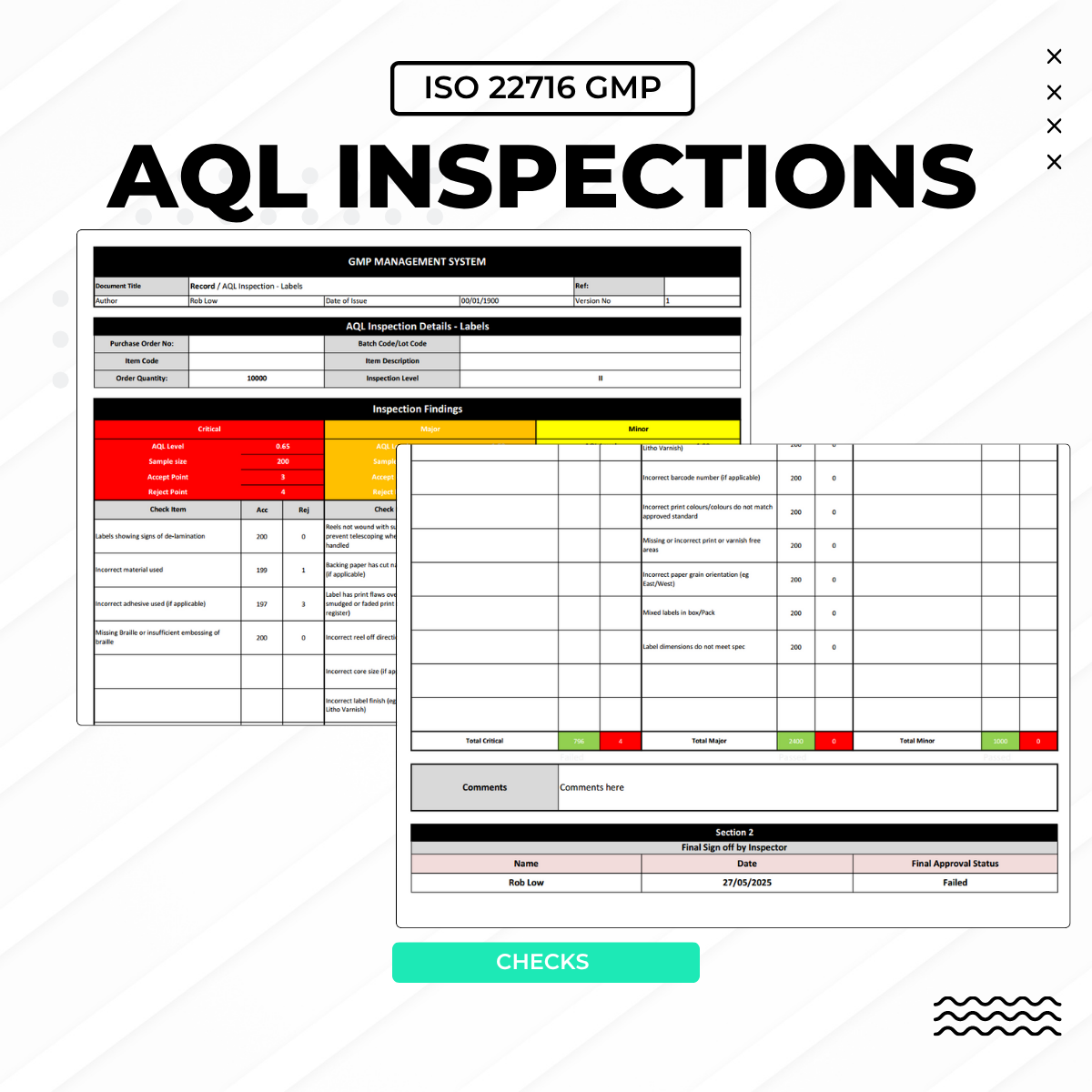

This pack includes five professionally formatted AQL checksheets aligned with ISO 2859-1:1999 (en) for efficient sampling inspections across key packaging and finished goods components.

Each template is designed to help streamline your incoming goods checks or finished product inspections based on statistically valid AQL sampling plans.

Upon purchase, you’ll receive:

-

Blank AQL Template (fully customizable)

-

AQL Template – Bottles

-

AQL Template – Caps

-

AQL Template – Shipping Cases

-

AQL Template – Labels

-

AQL Template – Packed Finished Stock

Each checksheet includes:

-

Fields for lot size, sample size, AQL level

-

Pre-set layout for documenting inspection results

-

Pass/Fail logic based on accept/reject limits

-

Notes/comments field for traceability and non-conformance details

Why Choose This Template Pack?

-

Aligned with ISO 2859-1:1999 – Based on industry-standard acceptance sampling methodology

-

Ready-to-Use Structure – Saves time and improves inspection consistency

-

Covers Key Product Types – Ideal for cosmetics, food, pharma, and general manufacturing

-

Fully Editable – Customize to match your internal procedures, acceptance limits, or specific product codes

Instant Digital Access

All templates are available for immediate download after purchase.

Who Is This For?

This template pack is ideal for:

-

QA teams performing incoming goods or line inspections

-

Sites working toward or maintaining GMP, ISO 9001, BRCGS, or ISO 22716 certification

-

Contract manufacturers managing component and packaging quality

-

Consultants and startups needing an inspection-ready documentation set

Template Format Overview

-

File type: .xlsx (Microsoft Excel)

-

Editable Fields: Product details, AQL level, sample size, results, inspector name, etc.

-

Includes:

-

General Blank Template

-

Bottles AQL Sheet

-

Caps AQL Sheet

-

Labels AQL Sheet

-

Shipping Cases AQL Sheet

-

Finished Product/Packaged Stock AQL Sheet

-

Important Notice – Please Read Before Use

These checksheets are not plug-and-play forms.

They require careful review and configuration to ensure they:

-

Align with your selected AQL level and product risk profile

-

Reflect your actual component specifications and defect criteria

-

Match your lot size ranges, sample plans, and acceptance thresholds

-

Comply with your internal QMS or customer requirements

AQL inspections should only be conducted by trained personnel familiar with ISO 2859-1 and your company’s non-conformance definitions. We recommend working with your QA team or a qualified quality consultant to ensure correct implementation.

Using these templates without appropriate customization or training may lead to incorrect acceptance/rejection decisions.

Reviews

There are no reviews yet.